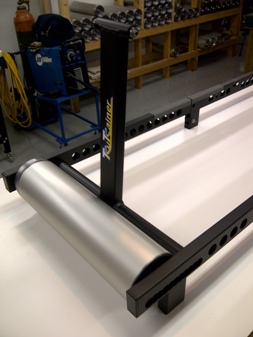

TruTrainer rollers are designed and manufactured by CycleDyne LLC, located in a suburb of Indianapolis, Indiana. CycleDyne LLC is a partnership between Ross Belloni and Jeff Rhodes. We are cycling enthusiasts who were not satisfied with our winter training experience using conventional rollers. We have been riding together since the 1980’s; and with short daylight and harsh Indiana winters our outdoor riding would be put on hold extended periods. So, each winter we would spend many hours on rollers waiting on spring and the opportunity to outdo the other on the bike. The problem was that other than helping develop balance, rollers did little to simulate a real world training experience. Power at a speed did not match the real world; sprinting or riding out of the saddle came nowhere close to the open road feel and the cyclic force “feedback” during each pedal stroke was completely inaccurate.

As well as being friends and avid cyclists, we are aerospace engineers with over 50 years experience designing and developing jet engines. So when one phoned the other and said “Hey, I've got an idea….why don’t we design and sell a better set of rollers”, the partnership was formed. Our goal was to devise a set of rollers that would come as close as possible to duplicating a real world bike riding experience. The TruTrainer design (patent pending) is the result of 15 years of basement engineering, design, and development.

Evaluations by amateur and professional cyclist alike have confirmed that TruTrainer rollers deliver a real world training experience. We believe that our rollers will exceed your training expectations for those days when it’s too dark, dangerous, or inclement to be outside on the bike. We've been training on them for six years now and our indoor training experience has never been better. The cycling team at Marian College agrees. We think our rollers have spoiled them because they can't stand to go back to their old ones. One Marian College standout, Jake Rytlewski, rode them for six hours straight one snowy Saturday. He then rode them for another three hours on Sunday!

2005 CycleDyne LLC formed

This was a hectic year for us and things did not always go according to plan. We wanted to have the production line up and running by August so that we would have plenty of time to market our rollers prior to fall-winter sales season. In late July, without advanced notice, our supplier of machined components backed out because they could not hold the aerospace tolerances that we had specified. Needless to say we burned a lot of midnight oil scrambling to recover for our first sales season. We were very happy with our first year, because the response from customers and reviewers has been overwhelmingly positive. Many customers tell us that they can’t stand to go back to their regular trainers or rollers.

2006 First European sale

The challenge of our second year was keeping up with sales. Word of our rollers was getting out thanks to some great reviews from Fixed Gear Fever, Pez Cycling News and NYVeloCity. Even people as far away as the UK were buying them and the compliments from the customers kept rolling in.

2007 Travelers introduced Q3

Now that our supply chain was set we decided to release the traveler version of our rollers. these are a light weight version of the TruTrainer without the rear flywheel and are targeted at the fixed gear guys who carry allot of gear to and from the velodrome. We also began marketing an upgrade kit to add the flywheel option for those who purchased travelers.

2008 Auxiliary load system begins development

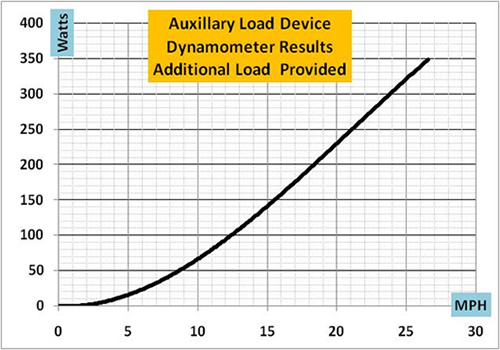

This year we began development of a wireless auxiliary load device that will allow you to get rid of your stationary trainers. The auxiliary load device is contained within the middle roller and is simple drop in retrofit that will allow hill climb load simulation. Our test results show that it will boost the existing load allowing 500 watts at 50 RPM in a 53x12 gear. Our plan was to begin marketing the auxiliary load device in the fall but issues with battery life and dependability with the electronics package have delayed us. The mechanicals are finished and the results of the testing of the production units are shown below. We are re-doing the electronics and moving to an ANT compliant system so that we will be compatible with your gizmos.

2009 Manufacturing in source

To make it easier to to provide the quality that we demand, we in sourced all of our manufacturing. No easy task, since we had to reconfigure our shop so that we could bring in our own CNC equipment. A lot of effort but the results are worth it. We owe a big thanks to the Hurco Machine Tool guys who are headquartered in Indianapolis for helping us get started. Our Hurco TM6 lathe and VM10 mill are pictured below.

CycleDyne LLC Machine Tools

2010 Production Capacity Increases

This year we focused on fine tuning our production systems so that we could keep up with demand without sacrificing quality. We think we were successful in provide the service levels our customers have come to expect even though we burned allot of midnight oil getting our production line humming. Most of our efforts revolved around creating the CNC machine tool programs along with requisite tooling and fixtures needed to produce our parts. We managed to increased our production capacity by eliminating setup time and increased part quality by designing and making precision fixtures to hold our parts while they are machined. This left little time to sort out the wireless auxiliary load system; and allot of work remains to sort out the ANT compliant electronics.

2011 Manually Adjustable Auxiliary Load Device Beta Release

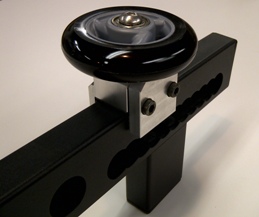

In order to satisfy owners who have been clamoring for more load. We released a beta auxiliary load bar to low rate production. We do not advertise this on our web site, but do sell it for $79.95 to those who contact us. Picture below is the load bar and manual adjustment mechanism.

The load bar that bolts onto the frame behind the middle roller. It uses the tapped holes pre-installed for the belt guard so the installation is fairly easy. it has four load positions from no load to full load. In the latter position, at 20 miles per hour the manual auxiliary device adds 200 watts of resistance. So high torque low RPM workouts in the 52x11 gear are possible. If you are interested, give us a shout and we'll get back to you.

2012 Front Fork Stand and Rail Bumpers Beta Release

We received some requests from owners wanting to do massive sprint intervals without worrying about coming off the rollers. So we went to the drawing board and come up with a front fork mount and rail bumpers that we beta released for testing. We do not offer them for sale through our web site, but will provide them as special order items if you contact us.

TruTrainer Premium Bicycle Rollers are engineered to bring the road to you anytime anywhere. We hope you experience the difference!

2013 Auxillary Load Bar, Front Wheel Bumpres and Front Fork Stand Production Release

We took the feedback from our beta release of these options and incorporated it to improve the design. This year we tooled up and production released these options. You can order them via our website with rollers or as stand alone options. we think you are going to like them.

2014 Auxillary Load Bar Patent Dispute

We have settled a patent dispute with our auxillary load bar and have agreed to stop marketing them. We are allowed to sell our remaining stock, but have removed this option from the website. If you want a load bar, drop us an e-mail at Infp@trutrainer.com and we can supply one while our supplies last.

Jeff and Ross